SurvivalFreak

Full Member

So after a year or so of compiling parts, and learning what I need to do to fix and upgrade the front end of my truck over the holidays I decided to start the process. I've run into a bump in the road though.

I've got new ES Control Arm bushing to be installed as the old stocks are pancake thin as well while I've got everything off I'm doing balljoints, tierods, pitman, idler, hubs ect...

The problem I'm facing Right Now is I cant seem to get the darn torsion bars out. I've used a 6ton 2Jaw gear puller and pulled the driver side Torsion key bolt and nut out, and I've tried lifting pressure on both the front Control Arm and the key where it sits in the torsion bar cross member, neither seems to help.

I found one crappy vid on youtube relating to a GM 1500 IFS and pulling the T-bars, the video was bad and the guy just kept saying how dangerous it was and such. Not being a wimp but does anyone have a trick to getting the Tbars out so you can pull the lower control arms to replace the bushings??

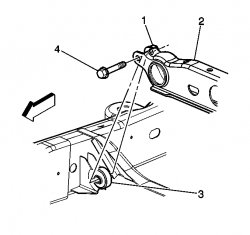

The following pictures show my setup, issue and attempted fix which isn't working.

This is how I got it supported, theres another pair of axle jacks on the frame by the torsion bar cross member.

The Torsion key with the bolt and nut out drops down and makes the tbar rest on the inside lip of the crossmember. I put a jack under to try and get enough clearance to get it out.

Looking from the front it almost appears that the Tbar is still "loaded" in so how would I go about getting it out from this now?

I tried using a pipe to wack it through the rear hole, didn't observe any noticible movement and after 10 minutes my arm was ready to fall off

All the steps I've done have been in reference to my Haynes manual Suspension and Steering Systems section -> Torsion Bar Removal and Installation Part. It says to take key bolt and nut out like I did, then Slide torsion bar to front of vehicle (I'm assuming it means through control arm) then remove torsion key, and bring torsion bar to rear dropping under torsion bar cross member to remove. Repeat for other side.

I'm confused, frustrated, and if the damn shop didn't want 2 grand to do this stuff labor alone I'd be rid of this headache. But alas challenge breeds character.

Any insight or tips would be greatly appreciated.

I've got new ES Control Arm bushing to be installed as the old stocks are pancake thin as well while I've got everything off I'm doing balljoints, tierods, pitman, idler, hubs ect...

The problem I'm facing Right Now is I cant seem to get the darn torsion bars out. I've used a 6ton 2Jaw gear puller and pulled the driver side Torsion key bolt and nut out, and I've tried lifting pressure on both the front Control Arm and the key where it sits in the torsion bar cross member, neither seems to help.

I found one crappy vid on youtube relating to a GM 1500 IFS and pulling the T-bars, the video was bad and the guy just kept saying how dangerous it was and such. Not being a wimp but does anyone have a trick to getting the Tbars out so you can pull the lower control arms to replace the bushings??

The following pictures show my setup, issue and attempted fix which isn't working.

This is how I got it supported, theres another pair of axle jacks on the frame by the torsion bar cross member.

The Torsion key with the bolt and nut out drops down and makes the tbar rest on the inside lip of the crossmember. I put a jack under to try and get enough clearance to get it out.

Looking from the front it almost appears that the Tbar is still "loaded" in so how would I go about getting it out from this now?

I tried using a pipe to wack it through the rear hole, didn't observe any noticible movement and after 10 minutes my arm was ready to fall off

All the steps I've done have been in reference to my Haynes manual Suspension and Steering Systems section -> Torsion Bar Removal and Installation Part. It says to take key bolt and nut out like I did, then Slide torsion bar to front of vehicle (I'm assuming it means through control arm) then remove torsion key, and bring torsion bar to rear dropping under torsion bar cross member to remove. Repeat for other side.

I'm confused, frustrated, and if the damn shop didn't want 2 grand to do this stuff labor alone I'd be rid of this headache. But alas challenge breeds character.

Any insight or tips would be greatly appreciated.